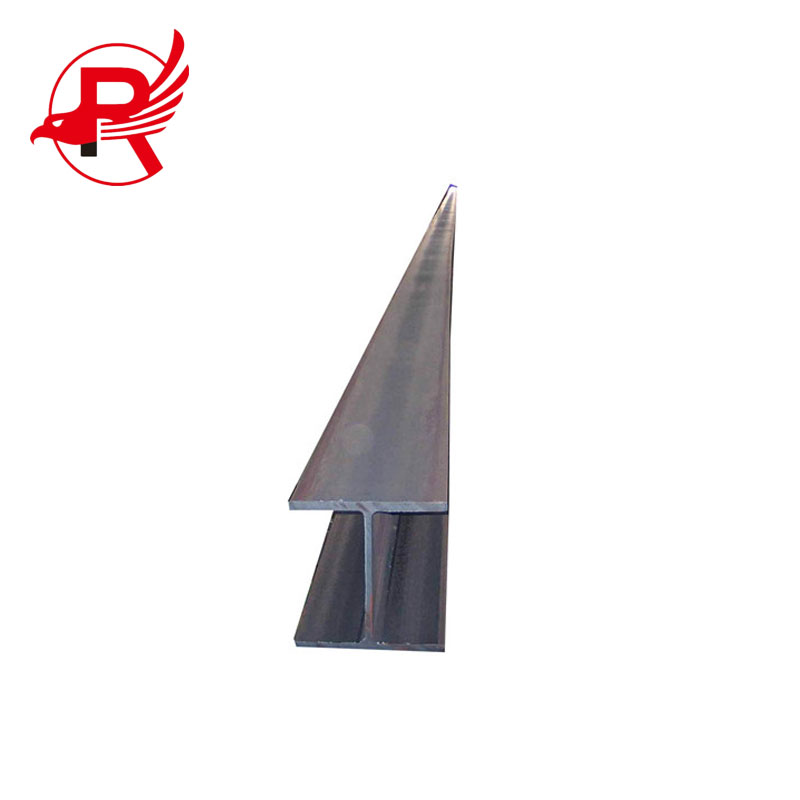

നിർമ്മാണത്തിനുള്ള ഉയർന്ന ഗ്രേഡ് Q345B 200*150mm കാർബൺ സ്റ്റീൽ വെൽഡഡ് ഗാൽവാനൈസ്ഡ് സ്റ്റീൽ എച്ച് ബീം

ഹോട്ട് റോൾഡ് എച്ച് ബീംകൂടുതൽ ഒപ്റ്റിമൈസ് ചെയ്ത സെക്ഷൻ ഏരിയ വിതരണവും കൂടുതൽ ന്യായമായ ശക്തി-ഭാര അനുപാതവുമുള്ള ഒരു കാര്യക്ഷമമായ ഭാഗമാണിത്. അതിന്റെ ക്രോസ് സെക്ഷൻ ഇംഗ്ലീഷ് അക്ഷരമായ "H" ന് തുല്യമായതിനാലാണ് ഇതിന് ഈ പേര് ലഭിച്ചത്. H- ആകൃതിയിലുള്ള സ്റ്റീലിന്റെ ഓരോ ഭാഗവും വലത് കോണുകളിൽ ക്രമീകരിച്ചിരിക്കുന്നതിനാൽ, H- ആകൃതിയിലുള്ള സ്റ്റീലിന് എല്ലാ ദിശകളിലും നിരവധി ഗുണങ്ങളുണ്ട്, ശക്തമായ വളയൽ പ്രതിരോധം, ലളിതമായ നിർമ്മാണം, ചെലവ് ലാഭിക്കൽ, ഭാരം കുറഞ്ഞ ഘടനാപരമായ ഭാരം തുടങ്ങി നിരവധി ഗുണങ്ങളുണ്ട്, കൂടാതെ ഇത് വ്യാപകമായി ഉപയോഗിക്കപ്പെടുന്നു.

H സെക്ഷൻ സ്റ്റീൽ എന്നത് മികച്ച മെക്കാനിക്കൽ ഗുണങ്ങളുള്ള ഒരു ഇക്കണോമി സെക്ഷൻ സ്റ്റീലാണ്, ഇത് I-സെക്ഷൻ സ്റ്റീലിൽ നിന്ന് ഒപ്റ്റിമൈസ് ചെയ്ത് വികസിപ്പിച്ചെടുത്തതാണ്. പ്രത്യേകിച്ച്, ഭാഗം "H" എന്ന അക്ഷരത്തിന് തുല്യമാണ്.

H-ബീമുകളെക്കുറിച്ചുള്ള ചില വിശദാംശങ്ങൾ ഇതാ:

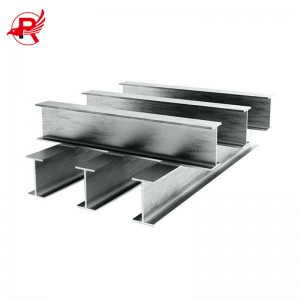

1. അളവുകൾ: H-ബീമുകൾ പല വലുപ്പങ്ങളിൽ വരുന്നു, ഉയരം, വീതി, വെബ് കനം എന്നിവയിൽ വ്യത്യസ്ത അളവുകൾ ഉണ്ട്. സ്റ്റാൻഡേർഡ് വലുപ്പങ്ങൾ 100x100mm മുതൽ 1000x300mm വരെയാണ്.

2. മെറ്റീരിയൽ: സ്റ്റീൽ, അലുമിനിയം അല്ലെങ്കിൽ സംയുക്ത വസ്തുക്കൾ പോലുള്ള വ്യത്യസ്ത വസ്തുക്കൾ ഉപയോഗിച്ച് H-ബീമുകൾ നിർമ്മിക്കാം.

3. ഭാരം: H-ബീമിന്റെ ഭാരം കണക്കാക്കുന്നത് ബീമിന്റെ വ്യാപ്തത്തെ വസ്തുവിന്റെ സാന്ദ്രത കൊണ്ട് ഗുണിച്ചാണ്. ബീമിന്റെ വലുപ്പവും വസ്തുവും അനുസരിച്ച് ഭാരം വ്യത്യാസപ്പെടുന്നു.

4. അപേക്ഷകൾ: പാലം നിർമ്മാണം, കെട്ടിട നിർമ്മാണം, ഭാരമേറിയ യന്ത്ര നിർമ്മാണം എന്നിവയുൾപ്പെടെ എച്ച്-ബീമുകൾ വ്യാപകമായി ഉപയോഗിക്കുന്നു.

5. ശക്തി: ഐ-ബീമിന്റെ ശക്തി നിർണ്ണയിക്കുന്നത് അതിന്റെ ബെയറിംഗ് ശേഷിയാണ്. ലോഡ് വഹിക്കാനുള്ള ശേഷി ബീമിന്റെ വലുപ്പം, മെറ്റീരിയൽ, ഡിസൈൻ എന്നിവയെ ആശ്രയിച്ചിരിക്കുന്നു.

6. ഇൻസ്റ്റലേഷൻ: H-ആകൃതിയിലുള്ള സ്റ്റീൽ സാധാരണയായി വെൽഡിംഗ് അല്ലെങ്കിൽ ബോൾട്ടിംഗ് സാങ്കേതികവിദ്യ ഉപയോഗിച്ചാണ് ഇൻസ്റ്റാൾ ചെയ്യുന്നത്. ബീമുകളുടെ വലുപ്പത്തെയും സ്ഥാനത്തെയും ആശ്രയിച്ചിരിക്കും ഇൻസ്റ്റാളേഷൻ പ്രക്രിയ.

7. ചെലവ്: വലിപ്പം, മെറ്റീരിയൽ, ഉൽപാദന രീതി എന്നിവ അനുസരിച്ച് എച്ച്-ബീമുകളുടെ വില വ്യത്യാസപ്പെടുന്നു. സ്റ്റീൽ എച്ച്-ബീമുകൾ അലുമിനിയം അല്ലെങ്കിൽ കോമ്പോസിറ്റ് എച്ച്-ബീമുകളെ അപേക്ഷിച്ച് വളരെ വിലകുറഞ്ഞതാണ്.

ഫീച്ചറുകൾ

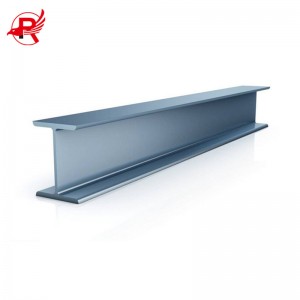

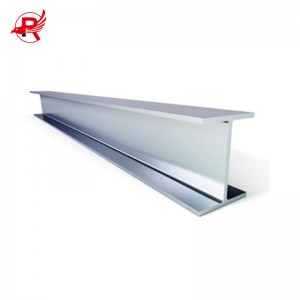

എച്ച് ബീം സ്റ്റീൽവലിയ ലാറ്റിൻ അക്ഷരമായ h ന് സമാനമായ ക്രോസ്-സെക്ഷൻ ആകൃതിയിലുള്ള ഒരു സാമ്പത്തിക പ്രൊഫൈലാണ്, ഇത് യൂണിവേഴ്സൽ സ്റ്റീൽ ബീമുകൾ, വൈഡ് ഫ്ലേഞ്ച് I-ബീമുകൾ അല്ലെങ്കിൽ പാരലൽ ഫ്ലേഞ്ച് I-ബീമുകൾ എന്നും അറിയപ്പെടുന്നു. H-ആകൃതിയിലുള്ള സ്റ്റീലിന്റെ വിഭാഗത്തിൽ സാധാരണയായി രണ്ട് ഭാഗങ്ങൾ ഉൾപ്പെടുന്നു: വെബ്, ഫ്ലേഞ്ച്, അരക്കെട്ട്, എഡ്ജ് എന്നും അറിയപ്പെടുന്നു. H-ആകൃതിയിലുള്ള സ്റ്റീലിന്റെ വെബ് കനം ഒരേ വെബ് ഉയരമുള്ള സാധാരണ I-ബീമുകളേക്കാൾ കുറവാണ്, കൂടാതെ ഫ്ലേഞ്ച് വീതി ഒരേ വെബ് ഉയരമുള്ള സാധാരണ I-ബീമുകളേക്കാൾ കൂടുതലാണ്, അതിനാൽ ഇതിനെ വൈഡ് ഫ്ലേഞ്ച് I-ബീമുകൾ എന്നും വിളിക്കുന്നു.

അപേക്ഷ

വ്യത്യസ്ത ആകൃതികൾ അനുസരിച്ച്, H-ബീമിന്റെ സെക്ഷൻ മോഡുലസ്, ഇനേർഷ്യ മൊമെന്റ്, അനുബന്ധ ശക്തി എന്നിവ സാധാരണ ബീമിനേക്കാൾ മികച്ചതാണ്.എച്ച് ബീംഒരേ മോണോമർ ഭാരത്തോടെ. വ്യത്യസ്ത ആവശ്യകതകളുള്ള ലോഹഘടനയിൽ, ബെയറിംഗ് ബെൻഡിംഗ് മൊമെന്റ്, പ്രഷർ ലോഡ്, എക്സെൻട്രിക് ലോഡ് എന്നിവയിൽ ഇത് മികച്ച പ്രകടനം കാണിക്കുന്നു, ഇത് സാധാരണ ഐ-സ്റ്റീലിനേക്കാൾ ബെയറിംഗ് ശേഷി വളരെയധികം മെച്ചപ്പെടുത്തുകയും 10% മുതൽ 40% വരെ ലോഹം ലാഭിക്കുകയും ചെയ്യും. H-ആകൃതിയിലുള്ള സ്റ്റീലിന് വിശാലമായ ഫ്ലേഞ്ച്, നേർത്ത വെബ്, നിരവധി സ്പെസിഫിക്കേഷനുകൾ, വഴക്കമുള്ള ഉപയോഗം എന്നിവയുണ്ട്.

പാരാമീറ്ററുകൾ

| ഉൽപ്പന്ന നാമം | H-ബീം |

| ഗ്രേഡ് | Q235B, SS400, ST37, SS41, A36 തുടങ്ങിയവ |

| ടൈപ്പ് ചെയ്യുക | ജിബി സ്റ്റാൻഡേർഡ്, യൂറോപ്യൻ സ്റ്റാൻഡേർഡ് |

| നീളം | സ്റ്റാൻഡേർഡ് 6 മീറ്ററും 12 മീറ്ററും അല്ലെങ്കിൽ ഉപഭോക്തൃ ആവശ്യാനുസരണം |

| സാങ്കേതികത | ഹോട്ട് റോൾഡ് |

| അപേക്ഷ | വിവിധ കെട്ടിട ഘടനകൾ, പാലങ്ങൾ, വാഹനങ്ങൾ, ബ്രാക്കറുകൾ, യന്ത്രങ്ങൾ മുതലായവയിൽ വ്യാപകമായി ഉപയോഗിക്കുന്നു. |

| വലുപ്പം | 1.വെബ് വീതി (H): 100-900mm 2.ഫ്ലാഞ്ച് വീതി (B): 100-300mm 3. വെബ് കനം (t1): 5-30mm 4. ഫ്ലേഞ്ച് കനം (t2): 5-30mm |

| നീളം | 1 മീ - 12 മീ, അല്ലെങ്കിൽ നിങ്ങളുടെ അഭ്യർത്ഥനകൾ അനുസരിച്ച്. |

| മെറ്റീരിയൽ | Q235B Q345B Q420C Q460C SS400 SS540 S235 S275 S355 A36 A572 G50 G60 |

| അപേക്ഷ | നിർമ്മാണ ഘടന |

| കണ്ടീഷനിംഗ് | സ്റ്റാൻഡേർഡ് പാക്കിംഗ് കയറ്റുമതി ചെയ്യുക അല്ലെങ്കിൽ ഉപഭോക്താക്കളുടെ ആവശ്യാനുസരണം |

സാമ്പിളുകൾ

Deലിവറി

ചോദ്യം: നിങ്ങളുടെ നിർമ്മാതാവാണോ?

എ: അതെ, ഞങ്ങൾ ഒരു നിർമ്മാതാവാണ്. ചൈനയിലെ ടിയാൻജിൻ സിറ്റിയിൽ ഞങ്ങൾക്ക് സ്വന്തമായി ഒരു ഫാക്ടറിയുണ്ട്.

ചോദ്യം: എനിക്ക് നിരവധി ടൺ മാത്രം ട്രയൽ ഓർഡർ ലഭിക്കുമോ?

എ: തീർച്ചയായും. എൽസിഎൽ സർവീസ് ഉപയോഗിച്ച് ഞങ്ങൾക്ക് നിങ്ങൾക്കായി കാർഗോ ഷിപ്പ് ചെയ്യാൻ കഴിയും. (കുറഞ്ഞ കണ്ടെയ്നർ ലോഡ്)

ചോദ്യം: സാമ്പിൾ സൗജന്യമാണെങ്കിൽ?

എ: സാമ്പിൾ സൗജന്യം, എന്നാൽ വാങ്ങുന്നയാൾ ചരക്കിന് പണം നൽകുന്നു.

ചോദ്യം: നിങ്ങൾ സ്വർണ്ണ വിതരണക്കാരനാണോ, വ്യാപാര ഉറപ്പ് നൽകുന്ന ആളാണോ?

എ: ഞങ്ങൾ ഏഴ് വർഷത്തെ സ്വർണ്ണ വിതരണക്കാരനാണ്, വ്യാപാര ഉറപ്പ് സ്വീകരിക്കുന്നു.